Conditioning Monitoring - Ensure Wayside Operation Efficiency with Industry Tailored EN 50121 and EN 50155 Solutions

Ensure Wayside Operation Efficiency with Industry Tailored EN 50121 and EN 50155 Solutions

Ensure Wayside Operation Efficiency with Industry Tailored EN 50121 and EN 50155 Solutions

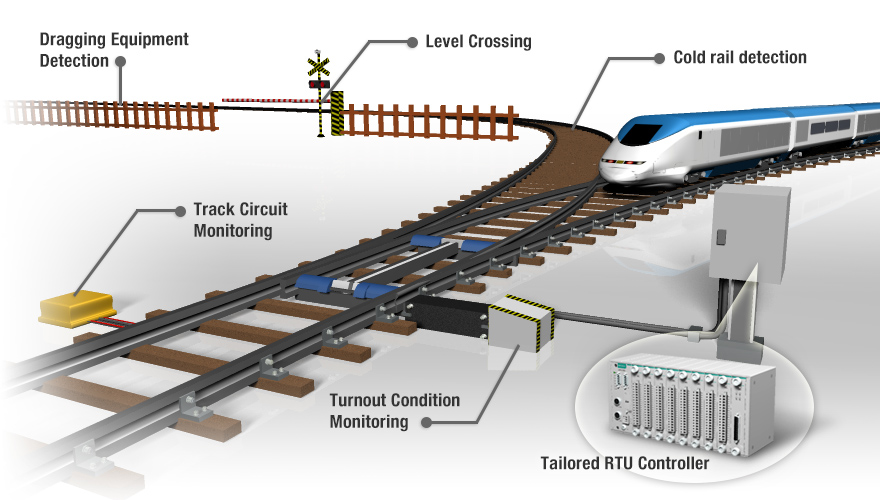

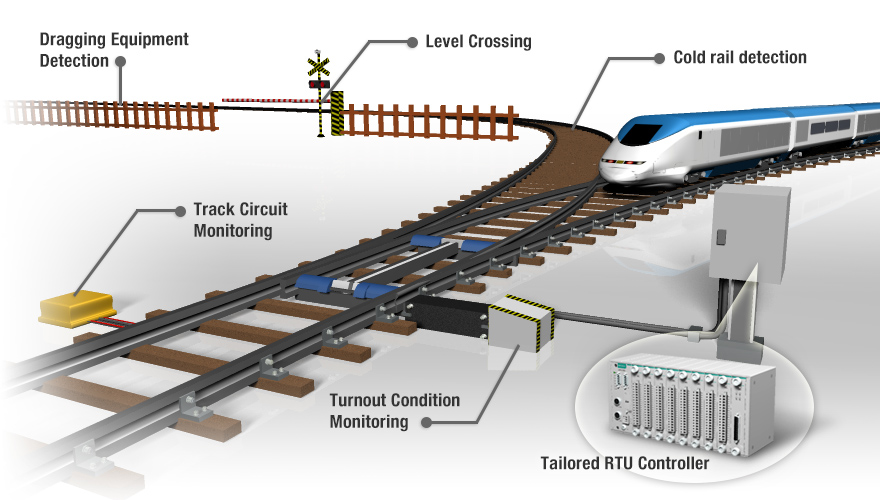

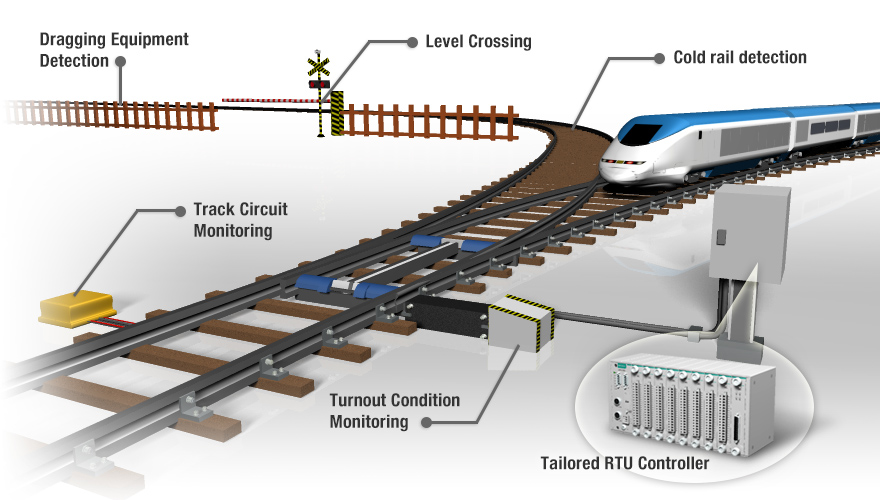

The high financial and reputational costs of railway accidents and long delays have led railway infrastructure managers to adopt increasingly sophisticated preventive maintenance systems. However, the ability of railway operators and maintenance engineers to prevent costly system failures and optimize resource allocation depends on myriad real-time wayside asset condition information provided by separate monitoring systems. These data acquisition systems are often comprised of many sensors, transducers, and remote terminal units running on different platforms and closed communication protocols, which can make maintenance more challenging and costly.

Moxa´s EN 50121-4 compliant modular RTU controllers are tailored for railway asset monitoring applications; and offer system integrators a more accurate, open platform field solution to collect large amounts of real-time condition monitoring data. Besides being easily and non-intrusively integrated and maintained, Moxa RTU controllers can monitor all critical assets from any remote location.

Turnout Condition Monitoring

The performance of turnout condition monitoring equipment can be measured by the amount of power the point machine needs to move the switch blades since a deviation in electrical current consumption may indicate a potential problem. Deploying RTU controllers at turnout filed sites can provide vital information about the point machine´s electrical current consumption, capacity, and phase angle. It is important to continuously monitor these key parameters in these applications to help management collect data, provide automated maintenance records, and support maintenance engineers in the field. Moxa´s RTU controllers can connect to an array of sensors, such as motor current sensors, force sensors, and open/close sensors, to record real-time measurements from the sensors. What´s more, installation is quick and easy without requiring any track intrusions.

Level Crossing Condition Monitoring

Level crossings are extremely important for preventing collisions between trains and road traffic, and require regular maintenance to ensure safety and reliability. Moxa RTU controllers guarantee safe and reliable operation of level crossings by providing real-time information about operating delays of the level crossing, statistical data about closing times, percentage of closing time during the day, number of passing trains, and more. In addition, Moxa´s RTU controllers can be used to monitor the status of a variety of equipment associated with railroad crossings, including sirens, warning lights, the status of motors, boom gate positions, and timers. Moreover, Moxa´s RTU controllers support C/C++ or IEC 61131-3 programming, which can be used to automatically trigger IP cameras for video surveillance to provide an immediate response to system failures or vandalism.

Moxa railway solutions for turnouts and level crossing

Easy Deployment, Integration, and Maintenance

Integrated Solution for Security and Maintenance

Wayside security monitoring capabilities can also be combined with the core railway asset monitoring system. For example, Moxa´s RTU controllers provide standard APIs for cameras and laser sensors, which enable infrastructure managers to integrate a security system with an asset monitoring system. By combining laser and video surveillance capabilities in a single system, maintenance engineers can immediately respond to system failures or vandalism.

The high financial and reputational costs of railway accidents and long delays have led railway infrastructure managers to adopt increasingly sophisticated preventive maintenance systems. However, the ability of railway operators and maintenance engineers to prevent costly system failures and optimize resource allocation depends on myriad real-time wayside asset condition information provided by separate monitoring systems. These data acquisition systems are often comprised of many sensors, transducers, and remote terminal units running on different platforms and closed communication protocols, which can make maintenance more challenging and costly.

Moxa´s EN 50121-4 compliant modular RTU controllers are tailored for railway asset monitoring applications; and offer system integrators a more accurate, open platform field solution to collect large amounts of real-time condition monitoring data. Besides being easily and non-intrusively integrated and maintained, Moxa RTU controllers can monitor all critical assets from any remote location.

Turnout Condition Monitoring

The performance of turnout condition monitoring equipment can be measured by the amount of power the point machine needs to move the switch blades since a deviation in electrical current consumption may indicate a potential problem. Deploying RTU controllers at turnout filed sites can provide vital information about the point machine´s electrical current consumption, capacity, and phase angle. It is important to continuously monitor these key parameters in these applications to help management collect data, provide automated maintenance records, and support maintenance engineers in the field. Moxa´s RTU controllers can connect to an array of sensors, such as motor current sensors, force sensors, and open/close sensors, to record real-time measurements from the sensors. What´s more, installation is quick and easy without requiring any track intrusions.

Level Crossing Condition Monitoring

Level crossings are extremely important for preventing collisions between trains and road traffic, and require regular maintenance to ensure safety and reliability. Moxa RTU controllers guarantee safe and reliable operation of level crossings by providing real-time information about operating delays of the level crossing, statistical data about closing times, percentage of closing time during the day, number of passing trains, and more. In addition, Moxa´s RTU controllers can be used to monitor the status of a variety of equipment associated with railroad crossings, including sirens, warning lights, the status of motors, boom gate positions, and timers. Moreover, Moxa´s RTU controllers support C/C++ or IEC 61131-3 programming, which can be used to automatically trigger IP cameras for video surveillance to provide an immediate response to system failures or vandalism.

Moxa railway solutions for turnouts and level crossing

- RTUs Tailored for Railway Asset Monitoring and Preventive Maintenance

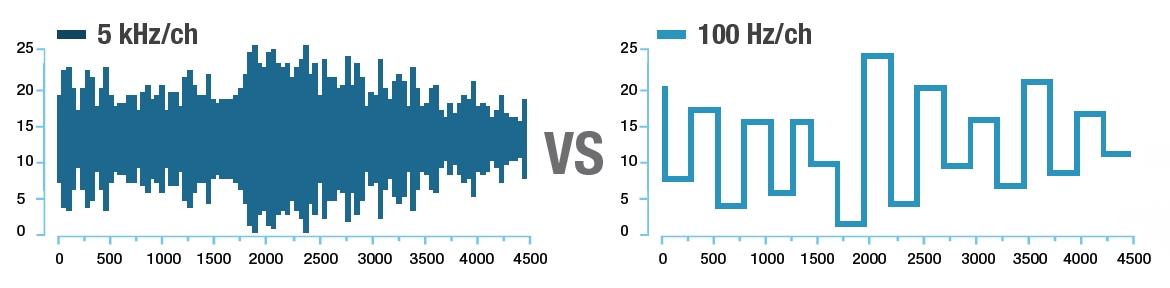

Precise data acquisition takes the trouble out of troubleshootingMoxa RTU controllers offer kHz-level analog input sampling rates, giving engineers the analog data accuracy they need to correctly analyze events with precise millisecond-level timestamps for event sequencing.

- Certified equipment for railway applications

Moxa´s RTU controllers are the world´s first RTU controllers that are compliant with the EN 50155, EN50121-3-2, and EN 50121-4 railway standards, which require products to withstand high levels of vibration.

- Extremely rugged with industry-leading MTBF

The high availability, -40 to 75°C wide operating temperature range, and high EMI immunity, which provides surge and ESD protection for the power and communication ports, of Moxa´s RTU controllers ensure the utmost reliability.

Easy Deployment, Integration, and Maintenance

- Support for all major programming language such as IEC 61131 and C/C++

Moxa´s RTU controllers support railway standard C/C++ and IEC 61131-3 programming, which enable easy integration with any system platform. - Hot-swappable modules save time for service visits

All the I/O modules on Moxa´s RTU controllers are hot-swappable so users can replace the modules without shutting down the system. The CPU will then automatically configure the new module. This intelligent architecture means that hardware can be easily upgraded and maintained without highly specialized knowledge or training. - Compact modular design for easier deployment

Moxa RTU controllers support a versatile collection of I/O modules. The non-intrusive, compact, and modular design makes Moxa RTU controllers ideal for wayside cabinets with limited space. - Easy System Configuration and Maintenance with RTUxpress

RTU controllers come equipped with an intuitive offline configuration tool?RTUxpress?that provides a user-friendly interface for device setup, tag management, and service configuration. This utility can help you reduce programming effort with ready-to-run services for alarms, data logging, and communication. RTUxpress also enables you to easily link I/O events and services with Moxa´s TagEasy feature

Integrated Solution for Security and Maintenance

Wayside security monitoring capabilities can also be combined with the core railway asset monitoring system. For example, Moxa´s RTU controllers provide standard APIs for cameras and laser sensors, which enable infrastructure managers to integrate a security system with an asset monitoring system. By combining laser and video surveillance capabilities in a single system, maintenance engineers can immediately respond to system failures or vandalism.