Improving the sampling rate of wafer production data acquisition

Advanced Process Control System (APC) has been used for many years to produce a superior product at a competitive cost.

Project Introduction:

In order to create even smaller devices, silicon wafers have had to greatly improve their quality. During their manufacturing process, wafer suppliers must continue to develop high-yield, simplified processes. Advanced Process Control System (APC) has been used for many years to produce a superior product at a competitive cost. As a result, accurate data collection is the key because APC technology relies on metrology applications. There are many repeated processes in the manufacture of wafers, all of which adopted fault detection and classification system (FDC) - a subsystem of APC - for the automatic detection of equipment problems and the execution of stoppages and alarms.

System Requirements:

A well-known wafer manufacturer was searching for an improved solution to its wafer polishing machine because the original sampling rate was too slow (one sample/sec), resulting in overdoing the grinding process. Replacing the machine wasn?t an option as it was still under warranty, so connecting external devices was the only possible solution to measuring the AC current of the grinding head motor without damaging the existing lines. It also needed to be able to send out the digital output signal of Normal Close (NC) to control the grinding head operation.

Project Implementation:

In order to create even smaller devices, silicon wafers have had to greatly improve their quality. During their manufacturing process, wafer suppliers must continue to develop high-yield, simplified processes. Advanced Process Control System (APC) has been used for many years to produce a superior product at a competitive cost. As a result, accurate data collection is the key because APC technology relies on metrology applications. There are many repeated processes in the manufacture of wafers, all of which adopted fault detection and classification system (FDC) - a subsystem of APC - for the automatic detection of equipment problems and the execution of stoppages and alarms.

System Requirements:

A well-known wafer manufacturer was searching for an improved solution to its wafer polishing machine because the original sampling rate was too slow (one sample/sec), resulting in overdoing the grinding process. Replacing the machine wasn?t an option as it was still under warranty, so connecting external devices was the only possible solution to measuring the AC current of the grinding head motor without damaging the existing lines. It also needed to be able to send out the digital output signal of Normal Close (NC) to control the grinding head operation.

Project Implementation:

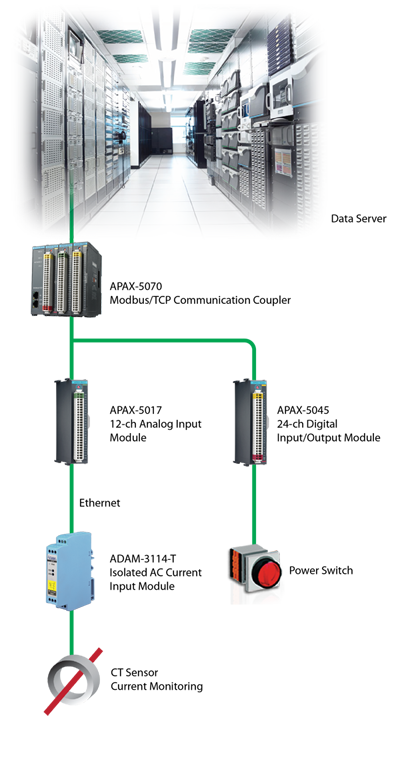

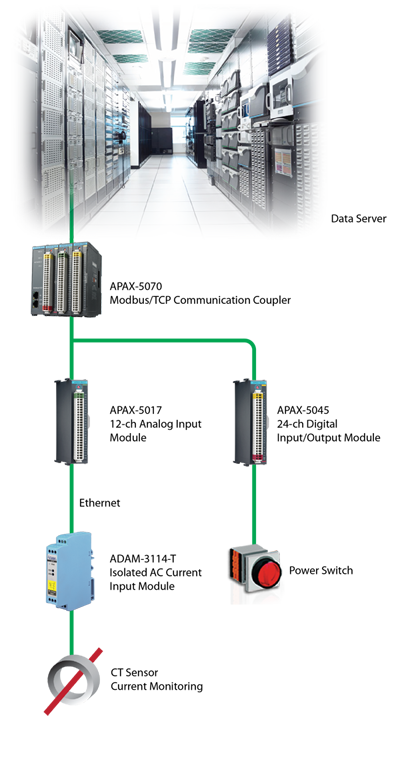

| ADAM-3114-T | Isolated AC Current Input Module |

| APAX-5017 | 12-ch Analog Input Module |

| APAX-5070 | Modbus/TCP Communication Coupler |

| APAX-5045 | 24-ch Digital Input/Output Module |

System Diagram: By using various I/O modules, Advantech provided the best non-invasive solution to improve the sampling rate of wafer production data acquisition as well as enhancing the performance of its manufacturing machines.Advantech?s ADAM-3114-T module and the serial products of APAX (including APAX-5017, APAX-5070 and APAX-5045) are installed in the control cabinet to enhance the sampling frequency (up to 3 samples/sec). Due to weak AC signals, Advantech provided a customized product - ADAM-3114-T, with an isolated AC current input signal conditioner, which amplifies the current signals from the sensor, and then sends this data to the APAX-5017 which is responsible for receiving the analog signals. Meanwhile, the APAX-5070 Modbus/TCP Communication Coupler, transmits thegrinding head motor data to the server via the Intranet so that the supervisor can check the machine?s operating status. If anything?s wrong the user can turn off the machine via the APAX-5045 Digital Input/Output Module which takes charge of the grinding head control via the Digital Output. Advantech also offers other options for the customer to upgrade their system. For example, under the same portfolio, users only need to add more channels and the sampling rate can be increased up to 20 samples per second or even more. Conclusion: Wafer fabrication is tough and complicated and new processes should be designed for each stage of development and inspection to allow for quicker production. Advantech?s range of high quality products ensured that not only are the customer?s needs met, but also that the user can produce moreitems, reduce scrap and improve uptime. Since this project has been finished for about a year and has shown excellent results, Advantech is now the first choice for any future projects. |  |